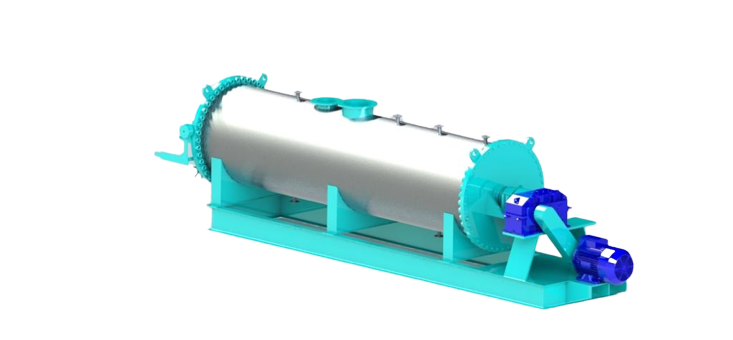

Rendering Plant Cooker / Batch Cooker

The cooker is utilized for the sterilization of animal by- products according to the ASME parameters that require working at minimum 133° C at minimum 3 bars for a minimum time of 20 minutes without interruption.

The material charge and discharge is automatically controlled by general panel control.

The cooker consists of a cylindrical shall with horizontal axis made with carbon steel, thickness 16 mm. with an external heating jacket of 16mm thick.

On the terminal parts of the device, rear as well as front, strong steel support is mounted to assure the perfect axial setting of the stirrer.

On the rear part, the reduction gear with parallel axes with help of very solid coupling and with the 40 HP motor driven with V-belts pulleys. Completed with drive guard.

The bronze stuffing box flanges, sliding on carbonized and ground steel bushings, assure a perfect seal of the stirrer shaft. The mixer shaft includes a tubular axis seamless pipe with 20mm wall thickness and tubular arms equipped with special stirring blades. Inside the tubular shaft and the blades, the steam circulation is installed. Completed with supporting frame work made with extra heavy tubing to alloy the weighing system.

Product Description

| Material | MS |

| Capacity | 6 Ton |

| Brand | ASE |

| Model Name/Number | ASE-BC-05 |

| Dimension | customize |

| Weight | 4-20 Ton |

| Power Load | 20 to 75 HP |

| Steam Pressure | 5 To 8 Bar |

| Surface Treatment | Color Coated |

| Hardness | 55 HRC |

| Tensile Strength | 410 MPa |